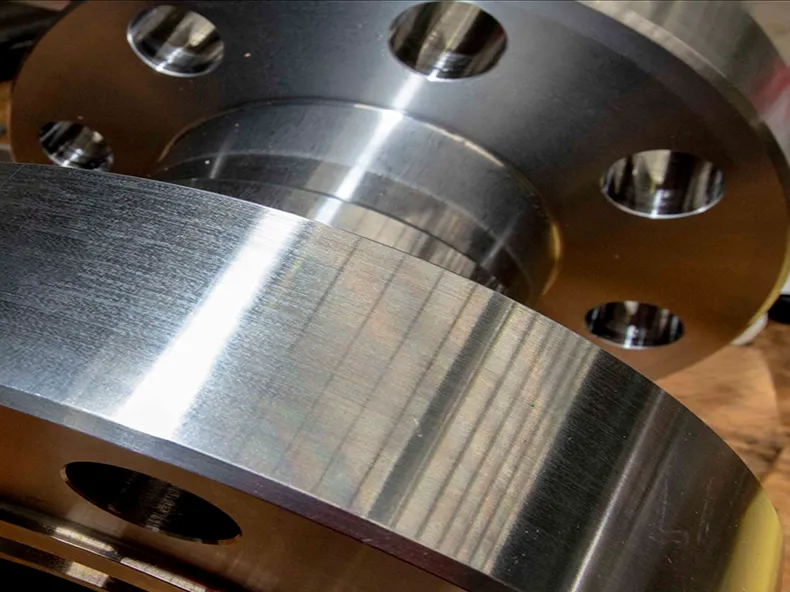

API 6A Flange

API 6A flanges are specialized components used in the oil and gas industry, designed according to the specifications set by the American Petroleum Institute (API). These flanges are critical for high-pressure and high-temperature applications, primarily in wellhead and Christmas tree equipment. API 6A flanges ensure a secure and leak-proof connection between various equipment and pipelines, facilitating the safe extraction and processing of hydrocarbons. They are manufactured from robust materials to withstand harsh environmental conditions and are available in various sizes and pressure ratings to meet industry demands. If you are interested in our API 6A flanges, please contact us.

REFINE BY

- Flange Manufacturer

- Flange standard

- Welding Neck Flange

- Stainless steel Flange

- Carbon & Alloy steel Flange

- Blind Flange

- Lap Joint Flange

- Orifice Flange

- Threaded Flange

- Swivel Ring Flange

- Reducing Flange

- Slip-On Flange

- Spectacle Blind Flange

- Compact Flange

- 1/2" (24)

- 3/4" (24)

- 1" (24)

- 1-1/4" (24)

- 1-1/2" (24)

- 2" (25)

- 2-1/2" (24)

- 3" (24)

- 4" (20)

- 4" (20)

- 304L (179)

- 316L (179)

API 6A Flange Models

Types And Configurations Of API 6A Flange

This type of flange has a neck that is fused to the pipe, offering exceptional structural integrity and resistance to deformation under high pressure and temperature conditions.

Used to close off or seal the end of a pipeline or valve, blind flanges do not have a bore and are typically used in testing or isolation scenarios.

These flanges have threads on the inner bore that match the pipe threads, allowing for easy assembly and disassembly without welding. They are commonly used in low-pressure and non-critical applications.

Slip-on flanges slide over the pipe and are then welded in place. They are easier to align than weld neck flanges and are used in applications with lower pressure and temperature requirements.

Similar to slip-on flanges, socket weld flanges are welded to the pipe but have a socket-like design where the pipe fits into the flange before welding. They provide good flow efficiency and are suitable for smaller pipe sizes and higher pressure applications.

Specifically designed for orifice metering of fluids, these flanges come with pairs of pressure taps and are used with orifice plates in flow measurement applications.

Materials Of API 6A Flange

Typically used in lower pressure and non-corrosive environments, carbon steel offers good strength and weldability at a relatively lower cost.

Grades such as 304, 316, and duplex stainless steels (e.g., 2205) are preferred for their corrosion resistance, especially in environments with high chloride content or sour gas conditions.

Including various grades such as ASTM A182 F22, F91, and F92, alloy steels provide enhanced mechanical properties, including higher tensile strength, hardness, and resistance to wear and corrosion.

API 6A Flange Applications

API 6A flanges are essential components in the oil and gas industry, widely used for their robustness and reliability in high-pressure and high-temperature applications. They are primarily deployed in critical areas such as wellhead and Christmas tree equipment, ensuring secure connections between casing strings and tubing hangers during drilling, completion, and production phases.

These flanges also play integral roles in manifold systems, facilitating efficient flow control and distribution of hydrocarbons between wells, pipelines, and processing facilities.

In refineries, petrochemical plants, and gas processing facilities, API 6A flanges are key in constructing pressure vessels, separators, and process equipment, providing dependable connections that withstand extreme operational conditions.

Additionally, they are vital in subsea applications, including subsea trees and manifolds, where their corrosion resistance and structural integrity are crucial in offshore environments. Whether for flow measurement, testing, or isolation purposes, API 6A flanges ensure safe operations and facilitate maintenance and inspections without compromising overall system integrity.

API 6A Flange Dimensions

API 6A flanges are available in a range of nominal pipe sizes, starting from NPS 1/2 (DN 15) up to NPS 36 (DN 900) or larger, depending on specific application requirements.

The diameter of the bolt circle varies depending on the flange size and pressure rating, determining the spacing and number of bolts required for assembly.

API 6A specifies the diameter of bolt holes, which accommodates bolts used to secure the flanges together. Bolt sizes and lengths are also standardized.

Flange thickness varies depending on the pressure rating and size of the flange. Thicker flanges are used for higher pressure applications to ensure structural integrity and resistance to deformation under load.

The hub diameter of API 6A flanges varies based on the nominal pipe size and pressure class, providing sufficient thickness and strength for welding and maintaining integrity under pressure.

API 6A Flange Market Availability

Regional Availability

Availability of API 6A flanges may vary by region, influenced by local demand, regulatory requirements, and logistical considerations. Major oil-producing regions and industrial hubs tend to have robust availability due to proximity to drilling and production activities.

Online Platforms

Many manufacturers and distributors offer API 6A flanges through online platforms and catalogs, facilitating easy access and procurement for customers globally. These platforms provide detailed product specifications, certifications, and pricing information to support purchasing decisions.

Customization And Technical Support

Suppliers often provide customization services to meet specific project requirements, including material selection, special coatings, and modifications to flange dimensions or configurations. Technical support for installation, maintenance, and troubleshooting is also typically available.

API 6A Flange Manufacturer

Elite Piping Manufacture Co., Ltd. is a leading provider of high-quality piping solutions, specializing in API 6A flanges designed for the oil and gas industry. With a strong commitment to precision engineering and rigorous quality control, Elite Piping delivers reliable and durable flanges that meet stringent industry standards. Our API 6A flanges are crafted to withstand high pressures and harsh environments, ensuring optimal performance and safety in critical applications. Elite Piping’s dedication to innovation and customer satisfaction positions us as a trusted partner for companies seeking top-tier piping components.

GET IN TOUCH

Company:

Elite Piping Manufacture Co., Ltd.

Factory Address:

Office # 805, Building No. 6 Poly Metropolitan, Yongshum Town, Tongzhou District, Beijing, China.

Contact Person:

Michael

Contact Numbers:

+86 186 1829 1381

Email:

elite@elitepiping.com