Anchor Flange

An anchor flange is a specialized component used in piping systems to secure and stabilize pipelines, preventing them from moving due to thermal expansion, pressure fluctuations, or external forces. Typically, it is welded to the pipe and anchored to a stable structure, effectively absorbing axial forces and maintaining alignment. Anchor flanges are essential in high-pressure and high-temperature applications, ensuring the reliability and security of the piping system by minimizing movement and potential damage. They are commonly used in industries such as oil and gas, petrochemical, and power generation. If you are interested in our anchor flanges, please contact us.

REFINE BY

- Flange Manufacturer

- Flange standard

- Welding Neck Flange

- Stainless steel Flange

- Carbon & Alloy steel Flange

- Blind Flange

- Lap Joint Flange

- Orifice Flange

- Threaded Flange

- Swivel Ring Flange

- Reducing Flange

- Slip-On Flange

- Spectacle Blind Flange

- Compact Flange

- 1/2" (24)

- 3/4" (24)

- 1" (24)

- 1-1/4" (24)

- 1-1/2" (24)

- 2" (25)

- 2-1/2" (24)

- 3" (24)

- 4" (20)

- 4" (20)

- 304L (179)

- 316L (179)

Anchor Flange Models

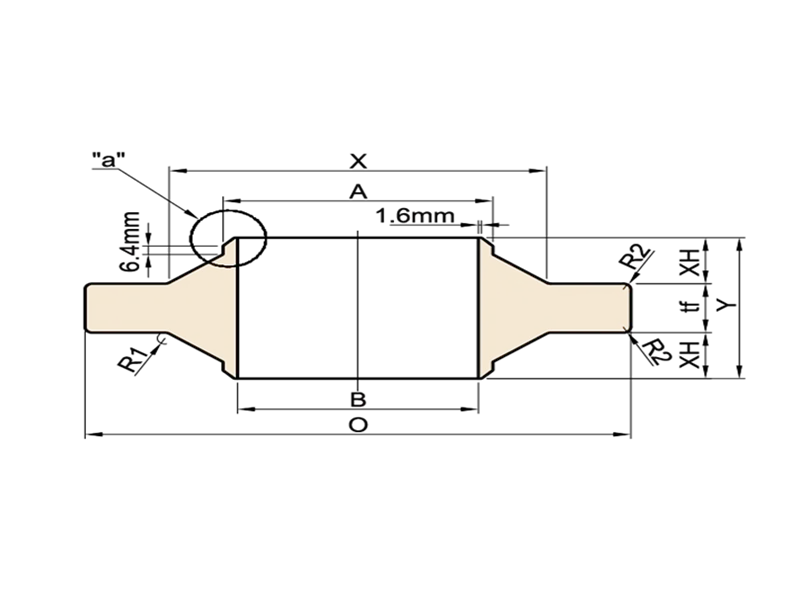

Design And Construction Of Anchor Flange

Design

Flange Plate

The main body, which provides the base for welding to the pipeline.

Bolt Holes

Arranged in a circular pattern to allow secure bolting to other flanges or anchor points.

Raised Face

Often included to improve sealing with gaskets.

Construction

Manufacturing Process

- Ensures high strength and durability, essential for high-pressure applications;

- Precise machining of the bolt holes, raised face, and other dimensions to meet exact specifications.

Welding

- Commonly used to attach the anchor flange to the pipeline, providing a strong and leak-proof connection;

- Must adhere to strict standards to ensure the reliability of the joint, often verified through non-destructive testing (NDT).

Anchoring

- Used to secure the flange to a fixed structure, such as a concrete foundation, ensuring stability;

- May include additional brackets or supports to distribute forces and prevent pipeline movement.

Materials Of Anchor Flange

Carbon steel anchor flanges offer strength and durability, making them suitable for various industrial applications. They are often used in pipelines where corrosion resistance is not the primary concern.

Stainless steel anchor flanges provide excellent corrosion resistance, making them well-suited for use in environments prone to corrosion or where hygiene and cleanliness are important. Grades such as 304, 316, and duplex stainless steels are commonly used depending on the specific requirements of the application.

Alloy steel anchor flanges offer enhanced mechanical properties and resistance to high temperatures. They are used in pipelines handling high-pressure fluids or in applications requiring resistance to elevated temperatures and corrosion.

Installation Of Anchor Flange

- Align the anchor flange with the pipeline and the anchor point or structure to which it will be attached;

- Use alignment tools as needed to ensure the flange is positioned correctly relative to the pipeline axis and the anchor point;

- Prepare the welding area by cleaning and degreasing to ensure a clean surface;

- Perform the welding process according to approved procedures, ensuring proper penetration and fusion between the anchor flange and the pipeline;

- Use welding techniques suitable for the material of the anchor flange and the pipeline, and verify the quality of welds through non-destructive testing (NDT) as required;

- Securely bolt the anchor flange to the pipeline and the anchor point;

- Use appropriate torque settings and methods to achieve proper bolt tension, ensuring a leak-free connection;

- Anchor the flange to a stable structure, such as a concrete foundation or support bracket;

- Use anchor bolts or other suitable fasteners to secure the flange and prevent movement under operational loads;

- Conduct pressure testing to verify the integrity and leak-tightness of the installed anchor flange and the entire pipeline system;

- Perform visual inspection and possibly non-destructive testing (NDT) to ensure weld quality and adherence to specifications.

Benefits And Advantages Of Anchor Flange

Stabilization And Support

Anchor flanges secure pipelines against axial movement caused by thermal expansion, pressure fluctuations, or external forces. This stabilization prevents damage to the pipeline and adjacent equipment, ensuring long-term reliability.

Enhanced Safety

By minimizing movement, anchor flanges reduce the risk of pipeline failure or leaks, enhancing overall safety in industrial environments where pipeline integrity is critical.

Alignment Maintenance

They help maintain alignment between pipeline sections and support structures, preventing misalignment that can lead to stress concentrations and premature wear.

Corrosion Resistance

Depending on the material chosen (e.g., stainless steel or specialty alloys), anchor flanges can provide excellent resistance to corrosion, extending the service life of the pipeline system in corrosive environments.

Operational Efficiency

Properly installed anchor flanges reduce the need for frequent maintenance and repairs associated with pipeline movement, resulting in enhanced operational effectiveness and minimized downtime.

Versatility

Available in various sizes, materials, and configurations, anchor flanges can be tailored to specific project requirements and environmental conditions, ensuring compatibility with diverse pipeline applications.

Standards And Specifications Of Anchor Flange

This standard covers dimensions, tolerances, materials, marking, and testing specifications for pipe flanges and fittings in sizes NPS 1/2 through NPS 24.

Specifically for flanges used in the oil and gas industry, API 6A provides specifications for wellhead and Christmas tree equipment, including flanges.

Various ASTM standards may apply depending on the material used for the anchor flange. For example, ASTM A105/A105M covers carbon steel forgings for piping applications.

International Organization for Standardization (ISO) standards such as ISO 7005-1 for metallic flanges and ISO 228-1 for pipe threads where applicable.

Depending on the project requirements, anchor flanges may need to comply with specific customer specifications or industry-specific standards.

Anchor Flange Manufacturer

Elite Piping Manufacture Co., Ltd. specializes in the production and supply of anchor flanges, catering to industrial sectors such as oil and gas, petrochemicals, power generation, and more. Known for our adherence to international standards and rigorous quality control measures, Elite Piping Manufacture Co., Ltd. offers a wide range of anchor flanges in various materials and configurations. Our products are designed to provide reliable support and stability for pipeline systems, ensuring durability, safety, and compliance with industry requirements. With a commitment to customer satisfaction and technical expertise, Elite Piping Manufacture Co., Ltd. serves as a trusted provider of high-quality anchor flanges globally.

GET IN TOUCH

Company:

Elite Piping Manufacture Co., Ltd.

Factory Address:

Office # 805, Building No. 6 Poly Metropolitan, Yongshum Town, Tongzhou District, Beijing, China.

Contact Person:

Michael

Contact Numbers:

+86 186 1829 1381

Email:

elite@elitepiping.com